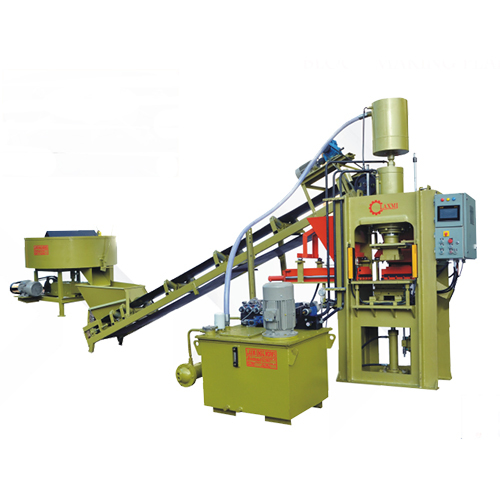

LM-03 Fully Automatic Paver Block Making Plant

Price 1200000 INR/ Piece

MOQ : 1 Piece

LM-03 Fully Automatic Paver Block Making Plant Specification

- Product Type

- Paver Block Making Plant

- General Use

- Industrial

- Method

- Hydraulic Press

- Processing

- Automatic

- Automatic

- Yes

- Power

- 32 HP (Total)

- Voltage

- 415 V

- Capacity

- 90 Ton Ton/day

- Weight (kg)

- Approx. 3800 Kg

- Brick Raw Material

- Cement, Fly Ash, Stone Dust, Coarse Aggregate

- Type

- Fully Automatic Plant

- Dimension (L*W*H)

- 4200 mm x 2200 mm x 2800 mm

- Color

- Green

- Vibration Type

- Heavy Duty 3 Motors

- Noise Level

- Low

- Operating Pressure

- 180 Bar

- Hydraulic Oil

- 68 Grade

- Labor Requirement

- 5-6 Persons per Shift

- Control System

- PLC Based Panel

- Oil Tank Capacity

- 400 Liters

- Pallet Size

- 900 mm x 900 mm

- Material Feeding

- Automatic Conveyor

- Cycle Time

- 15-18 seconds

- Moulding Area

- 870 mm x 870 mm

- Production Capacity

- 1800-2000 Blocks/Shift

About LM-03 Fully Automatic Paver Block Making Plant

Product details

|

Machine capacity |

90 Ton |

|

Country of Origin |

Made in India |

|

I Deal In |

New Only |

|

Power Steering |

Yes |

|

Machine Type |

Fully Automatic |

|

Automation Grade |

Automatic |

|

Model Name/Number |

LM - 03 |

|

Usage/Application |

Industrial |

High-Efficiency Production Capability

Designed to produce 1,8002,000 quality blocks per shift, the LM-03 maximizes throughput thanks to its fully automatic PLC-controlled system and fast cycle times. The plant delivers precision with a moulding area of 870870 mm, making it suitable for a variety of paver block sizes and applications.

Robust Engineering and Automation

Constructed to withstand industrial use, the plant integrates a heavy-duty hydraulic press, three vibration motors, and an automatic conveyor for seamless material feeding. The 400-liter tank, 68-grade hydraulic oil, and 180 Bar operating pressure offer excellent longevity, consistent performance, and minimal maintenance.

Operational Convenience and Safety

Operators benefit from intuitive PLC panel controls and automatic processes, reducing manual intervention and labor costs. Its low noise profile and safety-focused design ensure a comfortable and secure work environment, making it suitable for deployment in busy industrial settings.

FAQs of LM-03 Fully Automatic Paver Block Making Plant:

Q: How does the LM-03 Paver Block Making Plant automate the block production process?

A: The plant is equipped with a PLC-based control system and automatic conveyor, which seamlessly manage material feeding, hydraulic pressing, and block moulding. This automation ensures high productivity, uniform quality, and reduces manual labor, requiring only 56 operators per shift.Q: What raw materials are compatible with this paver block making plant?

A: The LM-03 is designed to efficiently process cement, fly ash, stone dust, and coarse aggregate. The automatic feeding system accommodates these materials, enabling consistent and versatile paver block production suitable for various construction requirements.Q: When is routine maintenance necessary for this plant, and how is it performed?

A: Routine maintenance primarily involves checking the hydraulic oil (68 grade), inspecting vibration motors, and ensuring the conveyor system operates smoothly. Typically, standard maintenance schedules are followed after every few hundred operating hours, as recommended in the user manual.Q: Where can the LM-03 Fully Automatic Plant be installed for optimal performance?

A: This plant is best installed in industrial environments with adequate electrical supply (415 V) and sufficient space to accommodate its dimensions (4200 mm x 2200 mm x 2800 mm). Proper site leveling and access to raw materials are also important for efficient operation.Q: What benefits does the automatic PLC-based system provide to block manufacturers?

A: The PLC-based system improves process reliability, accuracy, and safety. It optimizes energy use, reduces operator error, minimizes downtime, and allows for precise control over production variables, resulting in consistent, high-quality paver blocks.Q: How does the heavy-duty vibration system contribute to block quality?

A: The plants three heavy-duty vibration motors ensure thorough compaction of the concrete mix during the forming process. This leads to dense, high-strength blocks with excellent surface finish and structural integrity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paver Block Making Plant Category

Fully Automatic Paver Block Making Plant

Price 1150000.00 INR / Plant

Minimum Order Quantity : 1 Sheet

Voltage : 420 V

Method : Hydraulic Pressure

Capacity : 24003000 Blocks/Hour

Automatic : Yes

Fully Automatic Bricks And Block Making Machine With Batching Plant

Price 7500000 INR

Minimum Order Quantity : 1 Unit

Voltage : 415 V, 3 Phase, 50 Hz

Method : Other, Hydraulic Pressure / Vibro Type

Capacity : 12002000 Bricks/Hour (variable by model)

Automatic : Yes

"We are dealing in local area only."

LAXMI ENGINEERING WORKS

GST : 08BDAPM6344K1ZC

GST : 08BDAPM6344K1ZC

B/H Adarsh Nagar, Police Station, Beawar Road, Prabatpura, Ajmer - 305002, Rajasthan, India

Phone :08045811644

|

LAXMI ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry