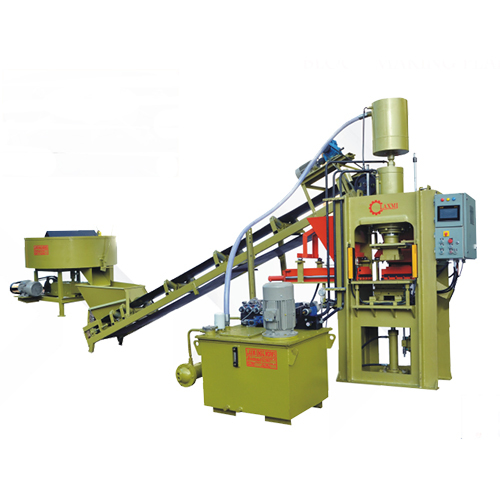

Fully Automatic Bricks And Block Making Machine With Batching Plant

MOQ : 1 Unit

Fully Automatic Bricks And Block Making Machine With Batching Plant Specification

- Method

- Hydraulic Pressure / Vibro Type

- Processing

- Brick Production

- Power

- 35-45 HP (varies with configuration)

- Voltage

- 415 V, 3 Phase, 50 Hz

- Capacity

- 1200-2000 Bricks/Hour (variable by model)

- Weight (kg)

- Approx. 3500-5000 kg

- Brick Raw Material

- Fly Ash, Cement, Sand, Aggregate, Water

- Type

- Fully Automatic Bricks And Block Making Machine With Batching Plant

- Dimension (L*W*H)

- 6100 mm x 2400 mm x 2900 mm (approx.)

- Color

- Standard (often Blue/Yellow as per image)

- Conveyor Belt Width

- 500 mm (approx.)

- Maintenance

- Low and Easy Maintenance Design

- Pallet Size

- 900 mm x 550 mm (approx., customizable)

- Vibration Force

- 60-80 kN (adjustable as per material)

- Molding Cycle Time

- 12-18 seconds per cycle

- Batching Plant Features

- Automatic Weighing and Mixing

- Noise Level

- < 85 dB

- Control System

- PLC Control with Touch Screen Interface

- Water Consumption

- 350-500 Liters/Day (depends on usage)

- Safety Features

- Overload Protection, Emergency Stop

- Number of Bricks Per Stroke

- 8-12 Standard Bricks (varies as per mold)

Fully Automatic Bricks And Block Making Machine With Batching Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- All India

About Fully Automatic Bricks And Block Making Machine With Batching Plant

Experience the ineffable innovation of our Fully Automatic Bricks And Block Making Machine With Batching Planta resplendent laureate in modern construction solutions. As a best-seller, this machine features PLC control with a touch screen interface for seamless operation, customizable pallet size, and lightning-quick molding cycles (12-18 seconds). With a vibration force of 60-80 kN and a capacity of up to 2,000 bricks per hour, productivity soars without compromise. Grab this discount opportunity and enjoy robust steel design, effortless maintenance, and advanced safety features for uninterrupted, high-volume success.

Advanced Features for Versatile Construction Needs

The Fully Automatic Bricks And Block Making Machine With Batching Plant is engineered for superior performance and broad utility. Designed for both construction professionals and industrial scale projects, it employs hydraulic pressure and vibro technology to produce high-quality bricks and blocks efficiently. Its automatic batching plant ensures consistent weighing and mixing, enhancing output quality. With strong steel construction and programmable PLC control, this machine is used as a reliable core asset for brick production, catering to exporters, manufacturers, and large-scale sites.

Packaging Details, Supply, and Secure Delivery

We maintain competitive list prices while ensuring that every machine is delivered using secure shipping methods to guarantee arrival in optimal condition. Standard packaging is robust, safeguarding against transit damage. Our supply ability accommodates bulk orders to meet dynamic project requirements. A sample policy applies for select clients considering a trial before making a commitment. Trust in our commitment to reliable logistics, transparent pricing, and consistent availability for both domestic and global customers.

Advanced Features for Versatile Construction Needs

The Fully Automatic Bricks And Block Making Machine With Batching Plant is engineered for superior performance and broad utility. Designed for both construction professionals and industrial scale projects, it employs hydraulic pressure and vibro technology to produce high-quality bricks and blocks efficiently. Its automatic batching plant ensures consistent weighing and mixing, enhancing output quality. With strong steel construction and programmable PLC control, this machine is used as a reliable core asset for brick production, catering to exporters, manufacturers, and large-scale sites.

Packaging Details, Supply, and Secure Delivery

We maintain competitive list prices while ensuring that every machine is delivered using secure shipping methods to guarantee arrival in optimal condition. Standard packaging is robust, safeguarding against transit damage. Our supply ability accommodates bulk orders to meet dynamic project requirements. A sample policy applies for select clients considering a trial before making a commitment. Trust in our commitment to reliable logistics, transparent pricing, and consistent availability for both domestic and global customers.

FAQs of Fully Automatic Bricks And Block Making Machine With Batching Plant:

Q: How does the PLC control system benefit the operation of this machine?

A: The PLC with a touch screen interface allows precise, user-friendly control, enabling operators to manage automated tasks easily, adjust settings rapidly, and minimize downtime for optimal brick production efficiency.Q: What raw materials can be used in the Fully Automatic Bricks And Block Making Machine?

A: This machine is compatible with fly ash, cement, sand, aggregate, and water, making it versatile for different material mixes as required in various local and international construction projects.Q: Where can this machine be used most effectively?

A: It is ideal for construction companies, brick manufacturers, and infrastructure projects, excelling in sites demanding high-capacity output and consistent brick or block quality.Q: What is the typical process and cycle time for molding bricks?

A: The machine completes a molding cycle in 12 to 18 seconds, producing 8 to 12 standard bricks per stroke, depending on the selected mold and material settings.Q: What maintenance is required for this machine?

A: The machine is designed for low and easy maintenance, with accessible components and safety features like overload protection and emergency stops, reducing downtime and enhancing operator peace of mind.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paver Block Making Plant Category

Fully Automatic Paver Block Making Plant

Price 1150000.00 INR / Plant

Minimum Order Quantity : 1 Sheet

Method : Hydraulic Pressure

Brick Raw Material : Other, Cement, Concrete, Fly Ash

Automatic : Yes

Product Type : Paver Block Making Plant

LM-03 Fully Automatic Paver Block Making Plant

Price 1200000 INR / Piece

Minimum Order Quantity : 1 Piece

Method : Other, Hydraulic Press

Brick Raw Material : Other, Cement, Fly Ash, Stone Dust, Coarse Aggregate

Automatic : Yes

Product Type : Paver Block Making Plant

"We are dealing in local area only."

LAXMI ENGINEERING WORKS

GST : 08BDAPM6344K1ZC

GST : 08BDAPM6344K1ZC

B/H Adarsh Nagar, Police Station, Beawar Road, Prabatpura, Ajmer - 305002, Rajasthan, India

Phone :08045811644

|

LAXMI ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry