Hollow-Solid Block Making Machine

Price 250000 INR/ Piece

Hollow-Solid Block Making Machine Specification

- Surface

- Painted

- Product Type

- Block Making Machine

- General Use

- Construction material manufacturing

- Material

- Metal

- Type

- Semi-Manual

- Capacity

- Standard

- Weight (kg)

- Varies based on mould size

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Method

- Mould-based pressing

- Dimension (L*W*H)

- Standard

- Feature

- Hollow and solid block making capability

- Color

- Green

- Warranty

- Standard Manufacturer Warranty

About Hollow-Solid Block Making Machine

Specification| Capacity | 250-275 Blocks per Hour |

| Block Type | Hollow & Solid Both |

| Usage/Application | Block And Bricks Making |

| Method | Hydraulic Press Cum Vibration Pattern |

| Automation Grade | Manual |

| Power | 5 KW |

| Material | Mild Steel |

| Brand/Make | Laxmi Engineering Works |

- Operating Pressure: 140 kg/cm (all)

- Model 1060 : Triple Vibrator

- Production Capacity 50 -55 stroke / hour: 400 x 200 x 100 mm 8 block / stroke, 400 x 200 x 150 mm 5 block / stroke, 400 x 200 x 200 mm 4 block / stroke

- Model 860: Double Vibrator Also Available

Efficient Construction Block Production

This semi-manual machine excels in the rapid creation of both hollow and solid blocks for the construction industry. Built with a sturdy metal frame, its manually operated press and easy-mould changing system allow for versatile output, making it a practical choice for small and medium-sized enterprises. Its reliability and flexibility help streamline block production without high automation costs.

Adaptability and User-Friendly Design

The machine's standard-sized structure accommodates varied moulds, enabling the production of different block sizes and types. Operators benefit from its straightforward manual controls and robust build, simplifying both operation and routine maintenance. Painted surfaces ensure a longer lifespan and easier cleaning, while the absence of computerized systems reduces operational complexity.

FAQ's of Hollow-Solid Block Making Machine:

Q: How does the hollow-solid block making machine operate?

A: This semi-manual machine utilizes a mould-based pressing method. Operators place raw materials into the mould, manually activate the pressing lever, and produce either hollow or solid blocks depending on the mould in use.Q: What materials can be used with this machine?

A: Typically, mixtures of cement, sand, aggregate, and water are used to form blocks. The mould and pressing method allow for both hollow and solid block production.Q: When should I perform maintenance on the machine?

A: Routine maintenance is recommended after every production cycle to ensure smooth operation and extend the machine's service life. Regular checks for wear, cleaning the painted surface, and lubricating moving parts are crucial.Q: Where can this machine be installed and used?

A: Its compact, standard dimensions make it suitable for use at construction sites, block manufacturing units, or any space with access to necessary utilities. It is widely used across India by manufacturers, traders, exporters, and suppliers.Q: What is the process to change between hollow and solid block production?

A: Changing production type involves swapping out the moulds to switch between hollow and solid shapes. The manual control system makes this process straightforward and efficient.Q: How does using this machine benefit my construction business?

A: The machine's adaptability, ease of use, and durable construction help streamline block manufacturing while reducing operational complexity and costs. Producing both hollow and solid blocks increases your project versatility.Q: Is technical expertise required to operate the device?

A: No specialized technical skills are needed as the machine features a manual control system. Basic training in mould handling and safety is sufficient for efficient operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Construction Machine Category

Semi Auto Fly Ash Brick Machine (Weigh Press Type)

Price 780000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Other, SemiAutomatic

Product Type : Semi Auto Fly Ash Brick Machine

General Use : Industrial

Computerized : No

Automatic Vibrator Table (Vibro) Plant

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Product Type : Automatic Vibrator Table

General Use : Vibrating concrete tiles and slabs for construction

Computerized : No

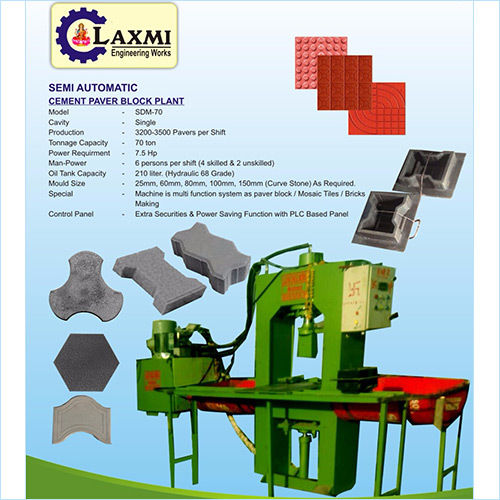

Semi Automatic Cement Paver Block Plant

Price 350000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Other, Semi Automatic

Product Type : Cement Paver Block Plant

General Use : Cement Paver Block Production

Computerized : No

Rotary Type Flyash Bricks Making Plant

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Rotary Type Flyash Bricks Making Plant

General Use : Flyash Brick Making

Computerized : Yes

GST : 08BDAPM6344K1ZC

|

LAXMI ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry