Concrete Block/Bricks Plant (Vibro type)

Price 800000 INR/ Piece

Concrete Block/Bricks Plant (Vibro type) Specification

- Motor Power

- 18.5 HP

- Lifting Height

- 3000 mm

- Surface

- Painted

- Lifting Speed

- 12 m/min

- Product Type

- Concrete Block Bricks Pant(Vibro type)

- General Use

- Construction

- Material

- Steel

- Type

- Vibro Type

- Capacity

- 2000-2500 blocks/8hr shift

- Weight (kg)

- 2500 kg

- Computerized

- No

- Automatic

- Semi Automatic

- Control System

- PLC Control

- Cooling System

- Air Cooling

- Method

- Hydraulic & Vibration

- Voltage

- 415V, 3 Phase

- Dimension (L*W*H)

- 2600 x 2000 x 2200 mm

- Feature

- Robust construction, Low maintenance

- Color

- Blue & Yellow

- Operating Temperature Range

- 5°C to 45°C

- Pallet Size

- 900 x 650 mm

- No. of Operators Required

- 3-4

- Max Block Size

- 400 x 200 x 200 mm

- Stationary/Movable

- Stationary

- Noise Level

- Less than 80 dB

- Spare Parts Availability

- Yes

- Vibration Frequency

- 4200 rpm

- Moulding Cycle

- 20-25 seconds

- Oil Tank Capacity

- 200 L

Concrete Block/Bricks Plant (Vibro type) Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Concrete Block/Bricks Plant (Vibro type)

Versatile Construction Solution for Commercial Applications

The Concrete Block/Bricks Plant (Vibro type) is specifically used in construction for producing durable concrete blocks and bricks. Its high output and sturdy construction make it the preferred choice for commercial builders, contractors, and infrastructure developers. Suitable for use in building residential complexes, industrial sites, or public infrastructure, this stationary plant excels in large-scale projects where speed, consistency, and quality are essential.

Avail Samples, Supply Ability, and Certifications at Lowest Price

Samples of this elite Concrete Block/Bricks Plant are available upon request, allowing you to examine quality before purchase. We offer reliable supply with a robust distribution network, ensuring prompt delivery at the lowest pricesignificantly below other list prices in the industry. Certified for quality and performance, this machines credentials ensure trust and value for every distributor, exporter, manufacturer, supplier, and trader across India.

FAQs of Concrete Block/Bricks Plant (Vibro type):

Q: How many operators are required to run this vibro type concrete block plant?

A: The stationary Concrete Block/Bricks Plant (Vibro type) requires 34 operators for smooth operation, ensuring efficient production and management of the workflow.Q: What are the primary uses for this concrete block/brick plant?

A: This plant is generally used for the construction industry, manufacturing durable concrete blocks and bricks suitable for residential buildings, industrial structures, and various infrastructure projects.Q: What is the process for producing blocks using this equipment?

A: Blocks are produced by combining hydraulic and vibration methods, with a rapid moulding cycle of 2025 seconds per batch, delivering high compression and precision for each block.Q: Where can I request a sample or professional quotation for this equipment?

A: You can contact the supplier or manufacturer directly to request a product sample or obtain a quotation at the lowest price. Samples are available for quality verification before placing bulk orders.Q: What are the main benefits of selecting this concrete block plant?

A: Choosing this plant offers advantages such as robust steel construction, low maintenance, matchless productivity (20002500 blocks/8hr shift), reliable spare parts availability, and favorable reviews from commercial users.Q: When should the hydraulic oil tank be refilled, and what is its capacity?

A: The oil tank has a 200-liter capacity. It should be refilled periodically, depending on the usage and maintenance schedule provided in the user manual.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Construction Machine Category

Semi Auto Fly Ash Brick Machine

Price 700000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Product Type : Semi Auto Fly Ash Brick Machine

Material : Steel

Computerized : No

Mini Reversible Mobile Concrete Mixer

Price 450000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Product Type : Concrete Mixer

Material : Steel

Computerized : No

Automatic Vibrator Table (Vibro) Plant

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Product Type : Automatic Vibrator Table

Material : Other, Metal

Computerized : No

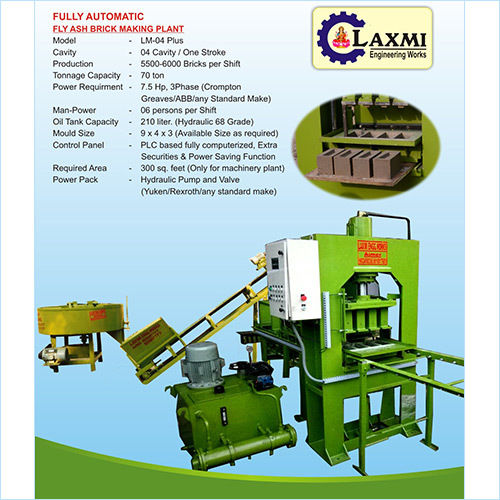

Fully Automatic Fly Ash Bricks Machine

Price 960000 INR / Plant

Minimum Order Quantity : 1 Plant

Control System : Other, PLC Control System

Product Type : Fully Automatic Fly Ash Bricks Machine

Material : Steel

Computerized : Yes

GST : 08BDAPM6344K1ZC

|

LAXMI ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry